Workplace Safety

Ensuring safety today is not just compliance with legal requirements, but also a moral duty to employees and their families, representatives of contractors and society.

Our activities comply with international standards ISO 45001-2018 “Management system in the field of occupational health and safety”, which applies to all employees of the Fund Group. Subsidiary-dependent organizations and their parent companies (78 organizations) have a certificate of conformity.

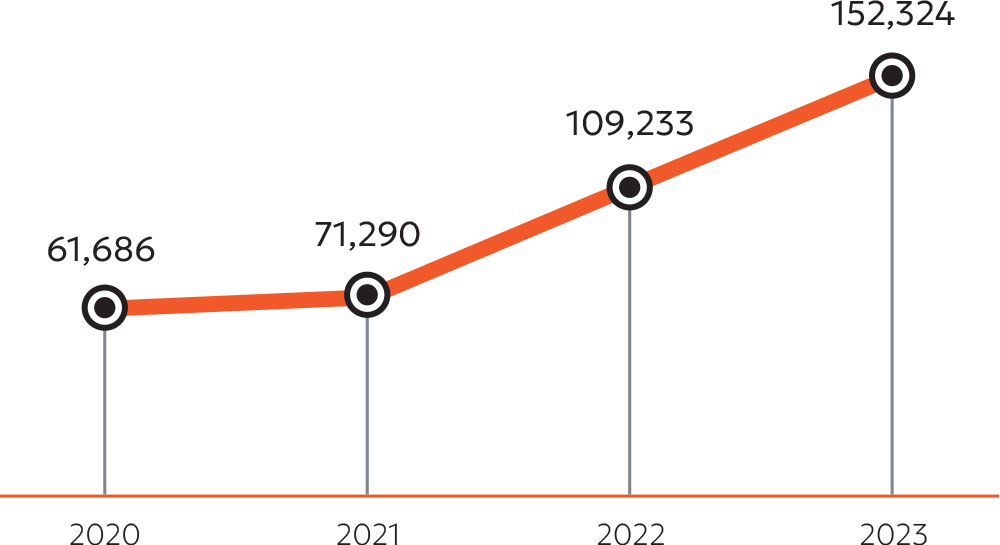

Number of employees in subsidiaries with ISO 45001-2018 certificate of compliance

We are constantly improving our work to ensure personal safety and accident-free production. Close interaction and exchange of practices with contracting companies are being built to improve and ensure workplace safety when performing work and providing services for the Fund Group. GRI 403-1 GRI 3-3

To strengthen the industrial safety function in the most critical large portfolio companies from its point of view, corresponding separate services have been created with direct administrative accountability of the function to the first managers.

We conduct workplace audits at various levels of management regularly throughout the year. The number of internal audits conducted for compliance with industrial safety requirements in 2023 reached 86,581 audits (61,916 audits in 2022). GRI 403-2

As it joined the world concept of “zero injuries Vision Zero”, the Fund revised its business models as part of the implementation of the “seven golden rules”: GRI 3-3:

1

Become a leader — show commitment to principles.

Every year, we conduct specialized events on industrial safety, such as forums, seminars, and master classes for managers, aimed at increasing leadership, commitment, and experience exchange. In addition, managers at the CEO-1 level of portfolio companies inspect production sites, visiting the enterprises at least once every two months.

2

Identify threats — control risks.

Proactive injury prevention tools are actively being introduced into the activities of portfolio companies, which are aimed at reducing risks, such as registering dangerous conditions, dangerous actions, potentially dangerous incidents (Near Miss), and conducting Behavioral safety observations. Every worker knows he or she has the right to suspend work that is unsafe. GRI 403-2

3

Define goals — develop programs.

The enterprises of the Fund’s group strive to achieve “zero injuries,” ensure a high level of labor protection and industrial and fire safety and protect the health of their employees from hazardous production factors. The Fund Group has approved the “Process Safety Action Plan for 2024”, consisting of 33 specific activities with established deadlines. Such plans are approved on an annual basis. GRI 403-9

4

Create a system of occupational safety and health — achieve a high level of organization.

Our activities are governed by the Occupational Safety Policy and the Corporate Occupational Safety Management Standard, which apply to our portfolio companies, their subsidiaries, affiliates and service providers. GRI 403-1 GRI 403-8 GRI 3-3

5

Ensure safety and hygiene in the workplace when working with machines and equipment.

To minimize the risks of accidents and accidents with severe and fatal outcomes at the level of portfolio companies, long-term Plans for the technical re-equipment of obsolete and physically worn-out equipment and structures are in place. Their updating is carried out in stages and is under employee's control at production units.

6

Improve your qualifications — develop professional skills.

To improve the competence of employees, personnel are regularly trained in courses and programs that go beyond the minimum legal requirements of the Republic of Kazakhstan.

7

Invest in people — motivate through participation.

The motivation and reward system allows us to constantly expand the circle of employees interested in the safety of production processes. Since 2022, the practice of awarding an annual nomination from the Chairman of the Board of Samruk-Kazyna JSC in the form of 1st place for achieving results in the field of industrial safety has been introduced. Large portfolio companies also hold competitions for innovative ideas in the field of industrial safety, for the best children’s drawing, and an Olympiad among occupational safety and health employees.

Work in accordance with the «7 golden rules» is carried out regularly. It is a set of systemic measures.

Achieving a zero level of accidents and incidents at work in the Group of Companies is not only due to the actions of its employees but also largely depends on the employees of contractors. In order to control compliance with the requirements of contractors' employees in the field of occupational safety, requirements on the availability of specialists in occupational health and safety (OHS), fire and industrial safety, as well as on the availability of trained personnel and tested knowledge of OHS, industrial safety and fire and technical minimum were introduced in the standard templates of contracts concluded through the portal zakup.sk.kz.

In addition to management, it is important for us to contribute to industrial safety by financing activities to prevent accidents, improve sanitary and living conditions for employees, improve employee health, purchase personal protective equipment, dry clean and wash work clothes, conduct training, and promote occupational safety issues.

Investments to ensure industrial safety, billion KZT

Key results for 2023

Every year, work in the field of industrial safety is built based on three main areas.

1 People and improving the level of safety culture

The Fund conducts training sessions and seminars to ensure employees and managers take a responsible approach to safety issues and demonstrate leadership and involvement by example.

In 2023, we trained 232,081 or 87% of employees within the framework of the requirements of the legislation of the Republic of Kazakhstan in the field of labor protection, industrial and fire safety, 59,176 or 22% of employees were trained in courses that go beyond the legislation of the Republic of Kazakhstan.

GRI 403-5The Fund’s employees undergo first aid training at international courses organized by Samruk Business Academy.

2 Ensuring safety during the operation of technological equipment

To ensure safety when working on equipment at the level of portfolio companies, “Plans for the technical re-equipment of morally and physically worn-out equipment and structures for 2023, for 2024-2027” have been developed for the operation of which there is an increased risk of accidents and accidents with severe and fatal outcomes.

We actively continue to work to prevent road accidents and reduce injuries among employees of the Fund’s Group of Companies. Thus, to develop the habit among employees of wearing seat belts in cars, practical testing of the “convincer” (a simulator of a frontal collision during an accident) was carried out in 10 cities of the Republic of Kazakhstan. GRI 403-9

Employees apply international best practices, including proactive accident prevention tools (registration of hazardous actions, conditions, potentially dangerous Near Miss incidents, conducting behavioral observations/safety audits, suspension of unsafe types of work using “stop cards”).

3 Prevention of emergency situations

A permanent Headquarters has been created in the Samruk-Kazyna JSC group of companies to regulate actions in case of accidents and emergencies.

To improve the labor protection and industrial safety system, the Fund’s Group of Companies conducts tactical exercises in hazardous industries.

We also regularly conduct cross-audits on industrial safety in portfolio companies and their branches. In total, we, together with company experts, conducted audits in 17 industrial enterprises. GRI 403-2

To ensure the required level of reporting transparency and development of communications in the field of industrial safety, several initiatives were implemented in the current reporting year regarding the digitalization of processes:

- dashboards on incidents were created to inform management about the current statistics of industrial injuries promptly;

- the «Log of information on events and incidents in contracting organizations of portfolio companies» and «Operational information on contractors in portfolio companies» were launched in the reporting management system;

- the practice of collecting and considering proposals from employees via QR and the practice of assessing the level of industrial safety by all employees of the Fund when on business trips to subsidiaries/branches of portfolio companies have been introduced. GRI 403-4

- forums in the field of digitalization are also held. NAC Kazatomprom JSC organized a forum dedicated to the digitalization of industrial safety in the city of Shymkent.

Statistics on occupational injury rates are monitored daily. The number of people injured due to industrial accidents was 120 in 2023. The assessment of occupational injuries included employees of portfolio companies engaged in production activities. GRI 403-9

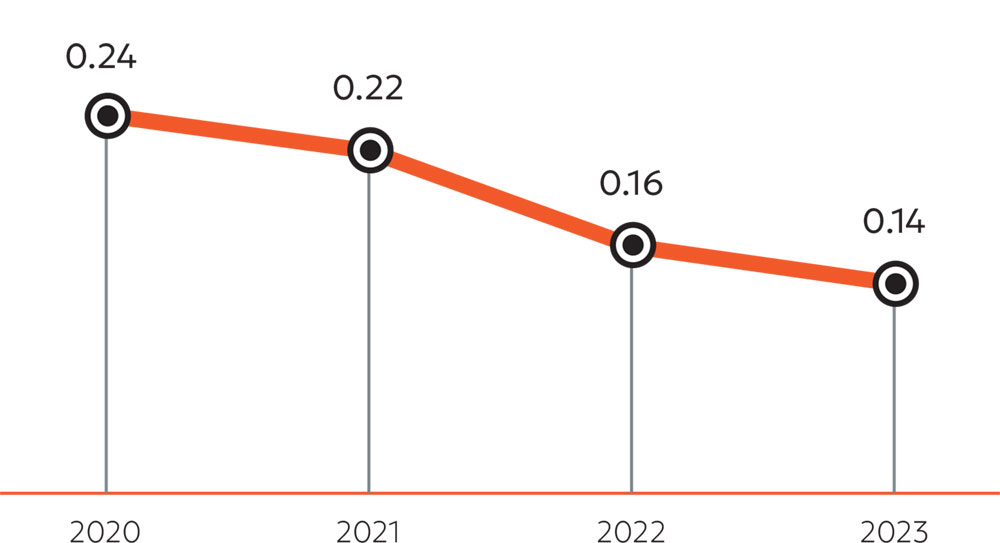

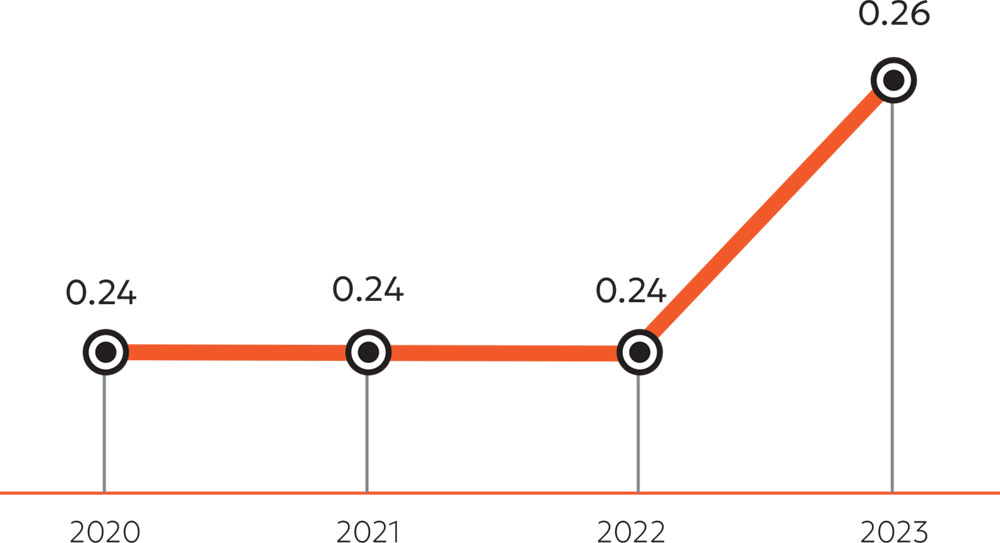

Lost time injury rate (LTIF), units

Lost Time Injury Frequency Rate (LTIFR)37, units

37 LTIFR (Lost Time Injury Frequency Rate) — the number of the company's employees injured in lost time accidents attributed to a light and severe work injury according to the work injury severity report (including fatalities) multiplied by 1 million man-hours and divided by the total number of man-hours worked during the 12 reporting months.

The Fund’s work-related serious injury rate began to be calculated in 2022 and amounted to 0.10 in 2023, which is a 12% decrease compared to the base year of calculation.

Based on the hazards that create the risk of injury with severe consequences, the Fund’s portfolio companies develop their own industrial safety action plans to prevent occupational injuries and proactively reduce risks and threats in the workplace. GRI 403-9

Despite our efforts, there were 11 fatalities in 2023 (12 cases in 2022): at JSC NC Kazakhstan Temir Zholy — 6, Samruk-Energy JSC — 2, NC KazMunayGas JSC — 2 , JSC NC QazaqGaz — 1. GRI 403-9

In 2023, the majority of serious injury incidents involve falls, electrical shocks, motor vehicle accidents, and exposure to moving, flying, or rotating objects. GRI 403-9

An important aspect is the analysis and investigation of incidents that occur at work and the adoption of measures to prevent their recurrence in the future. For each case, an analysis is carried out, and newsletters are sent out with a brief description of the circumstances, reasons, and corrective measures taken to prevent their recurrence in other companies ompo. GRI 403-1 GRI 403-2 In addition, we aim to achieve LTIF 0.12 by 2027. Additionally, the KPIs of portfolio companies include registration of behavioral safety observations, health and safety cards, audits of contractors, and others, which should positively impact minimizing injury cases.